Your garage door may seem like a simple, straightforward structure, but it’s full of intricately linked parts and good at keeping secrets from you. Even when it seems to be working fine, components could be wearing out or starting to malfunction behind the scenes. Maintenance – starting with our 21-point inspection – is essential to ensure smooth operation, extend the door’s lifespan, and prevent unexpected breakdowns. At least once a year, you need to Garager That!!!

Along with knowing the ins and outs of various types of garage doors, we’re familiar with the ways our South Florida climate can affect them. Hurricanes bring dangerously high winds that can destroy a garage door, while heat, intense sunlight, and high humidity can harm some of its materials with rust, warping, and excess moisture.

Aside from allowing us to assess the health and safety of your garage door, the inspection provides an opportunity to let you know exactly what’s working well and what needs help. We’ll answer your questions and explain your options for restoring the door to peak functioning or upgrading to a brand-new one that maximizes the chances of trouble-free operation for many years to come. We always want you to be in the driver’s seat when it comes to picking the service that best suits your needs.

What We Check During a 21-Point Inspection

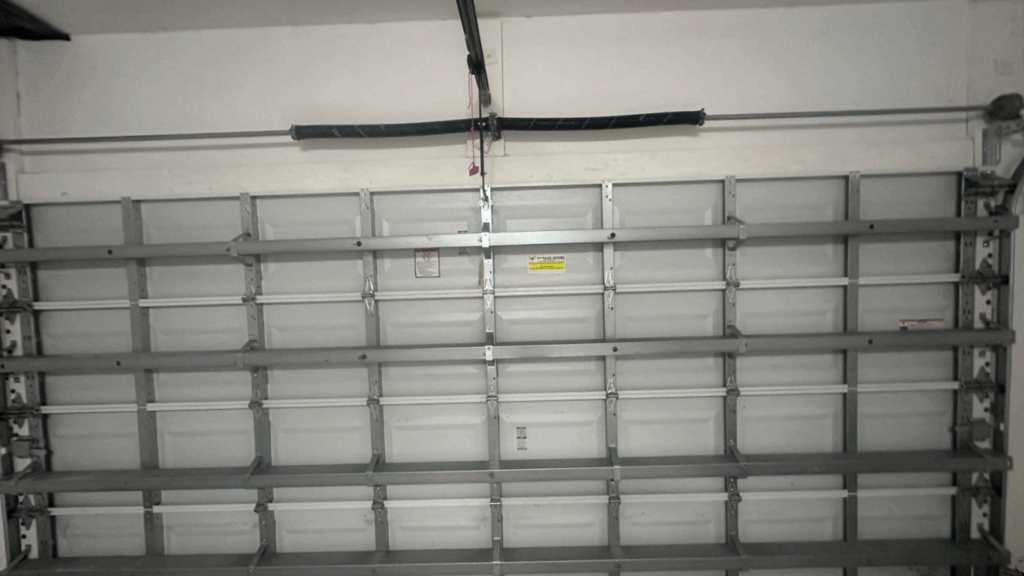

Every part of your garage door system plays a role in its performance and safety. One of the first things we evaluate is how the door moves, whether it opens smoothly, stays balanced at different heights, and remains level both on the ground and in the air. These early indicators often reveal deeper issues with tension, alignment, or wear.

Our 21-point inspection covers all critical components in two major areas: the mechanical system and the motor/control system. Each point is assessed based on known signs of wear, function, and safety risks.

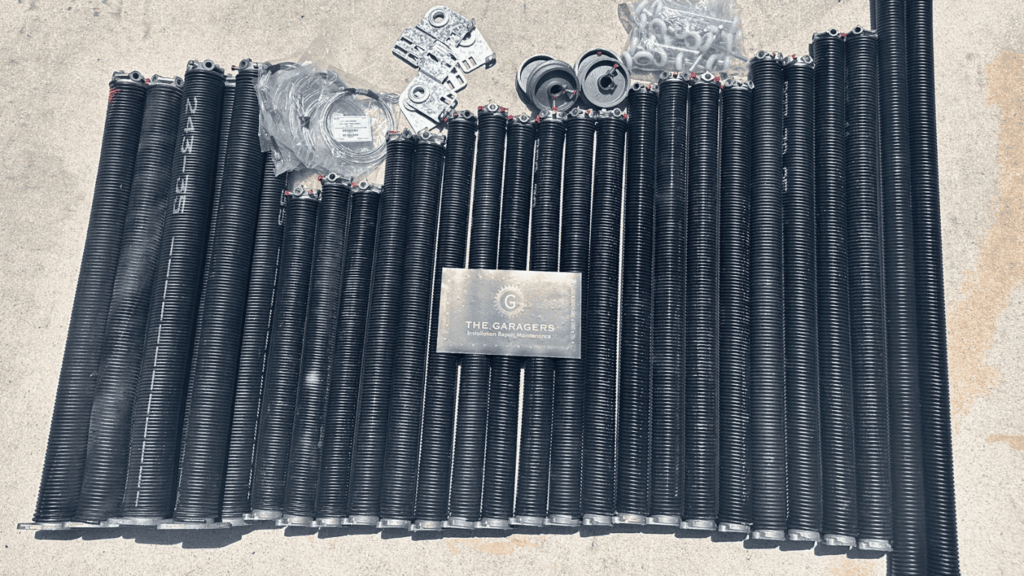

- Torsion Springs

We check for proper size, winding, and tension. Springs should allow the door to stay in place when raised a few inches, halfway, or fully. If the door drops, the springs may be unbalanced, the wrong size, or improperly installed. Sometimes technicians don’t have the right size springs with them, so they install what they have on hand to get the installation over with. Springs typically last 7- 10 years. We also check for signs of stretching or corrosion. - Torsion Tube

We inspect the torsion tube for alignment and signs of wear or warping. We inspect for any contact with moving parts that may cut or score the tube. An uneven or damaged tube can throw off the door’s balance and stress other components. - Torsion Drums

We listen for grinding or friction and visually inspect for signs of cable fraying around the drums. Proper drum function ensures cables wind evenly and the door lifts uniformly. - Torsion Cables

Cables are checked for rust, fraying, and wear. In older doors, oxidation is common and dangerous. If the cable tension feels off or signs of damage appear, we recommend replacement to avoid failure. - End Bearings

We check for steel dust around the end bearings, which indicates grinding and internal wear. These components must rotate smoothly to support the torsion system. - Center/Main Bearing

Similar to end bearings, the center bearing is inspected for alignment, wear, and noise. Misalignment can affect the torsion system’s performance. - Spring Bracket

We check to ensure bolts are tight and the bracket is secure. Loose or missing bolts here are a major safety risk.

8. Operator Bracket & J-Arm

We inspect for solid mounting and alignment. This connection must allow the motor to engage and disengage smoothly.

- Bottom Brackets

Bottom brackets hold the cable system in place. We inspect for rust, cracks, and secure mounting, as damage here compromises cable function. - Hinges & Top Brackets

We listen for creaking, check for cracking, and verify that the door panels are firmly connected. Loose or noisy hinges often mean wear is starting. - Rollers

Rollers are checked for grinding, squealing, or uneven movement. Proper rollers keep the door aligned and quiet. Noise here may also indicate dry hinges. - Tracks (Vertical & Horizontal)

We inspect for dents, misalignment, or signs of the door catching. We also watch and listen for any part of the door scraping the frame during operation, which can point to alignment issues or damaged track hardware. A smooth flow through the tracks is critical for safety and consistent movement. - Jamb Brackets/Door Bucks

These structural supports are inspected for looseness, bending, or corrosion. They must hold the full weight of the door in operation. - Panels

We check for sagging, warping, or misalignment. Damaged panels affect the door’s performance and can throw off the balance. We make sure each panel sits flush against the frame when closed. Gaps or uneven contact may indicate panel warping or frame misalignment. In South Florida, we also check if your garage door meets current wind-load code standards for structural integrity and safety. - Bottom Rubber & Retainer

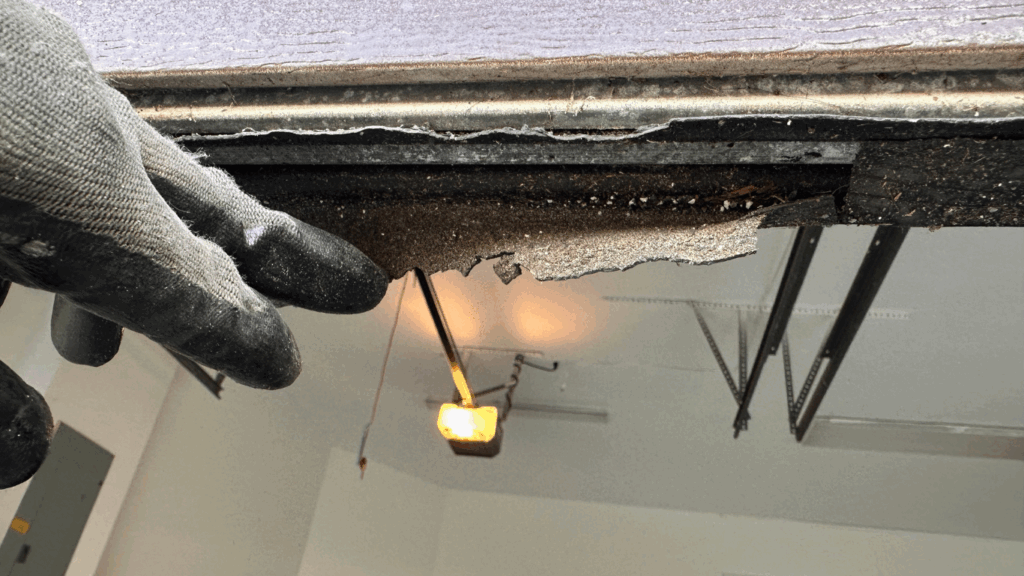

We inspect for dryness, cracking, or gaps that may allow water or pests to enter. If the rubber no longer seals properly, it needs replacing. - Vinyl Weatherstripping

This is inspected for proper fit and condition. Deteriorated weatherstripping reduces energy efficiency and invites moisture inside.

Motor & Control system:

- Motor/Safety Eyes

We begin by observing the motor’s sound and responsiveness. Excess noise can signal internal wear. We also ensure the safety sensors are aligned and functional, as misalignment may prevent the door from closing. - Belt

The belt is checked for cracking, stretching, or slack. A worn belt can cause jerky movement and put strain on the motor. - Trolley

We verify the trolley moves smoothly along the rail and properly engages and disengages. Resistance here may indicate buildup or worn gears. - Gear and Sprocket

We inspect for grinding, skipping, or excessive wear, which often appear in older or overworked motors.

21. Circuit Board/Remotes

Finally, we check the logic board and remotes for connectivity and response time. Faulty boards or unresponsive remotes often lead to inconsistent performance.

Each point we inspect is backed by real-world signs and symptoms: misalignment, unusual sounds, rust, wear, imbalance, or failure to hold position. When you hear creaking hinges or your garage door doesn’t stay open on its own, there’s a reason. Our inspection is designed to find it, and fix it before it becomes a costly repair.

What an Inspection Can Reveal

We recently performed an inspection on an older garage door system, which perfectly illustrates the kinds of issues that can build up over time without regular maintenance. While every home is different, many of the problems we found are common, and often preventable.

This particular door had worn springs that weren’t the right size for the door, leading to improper balance and extra strain on the motor. The cables were oxidized and frayed. The weather seal had hardened and cracked, letting water leak into the garage. A new motor, new springs, new cables, and a fresh seal were all needed to bring the door back to safe, quiet operation.

After repairs, the door passed its “final exam”: it held steady when lifted manually, operated smoothly under motor power, and stayed in place when opened by hand. It’s now safe, secure, and running like new.

Peace of Mind, One Door at a Time

There’s much more to a garage door than meets the eye. Prevent costly breakdowns with our affordable inspections and maintenance programs that keep your garage door system running smoothly year-round. They’re an important part of The Garagers’ commitment to providing our clients with peace of mind, one door at a time.